Views: 0 Author: Site Editor Publish Time: 2025-06-16 Origin: Site

The complexity of modern ship power systems poses unprecedented challenges to operation and maintenance management. In traditional ship management, oil quality testing usually adopts offline laboratory analysis, which has problems such as monitoring lag and information fragmentation. The online oil monitoring technology constructs a dynamic evaluation system for equipment health status by real-time collection of performance parameters of lubricating oil, fuel oil, and hydraulic oil. This technology not only prevents mechanical failures and extends equipment life, but also plays a key role in compliance with the International Maritime Organization (IMO) environmental regulations. With the integration of Internet of Things and artificial intelligence technology, online monitoring of oil products has evolved from a single functional sensor to a core platform covering the entire lifecycle health management of ship power systems, promoting the strategic transformation of the shipping industry from "passive maintenance" to "active prevention".

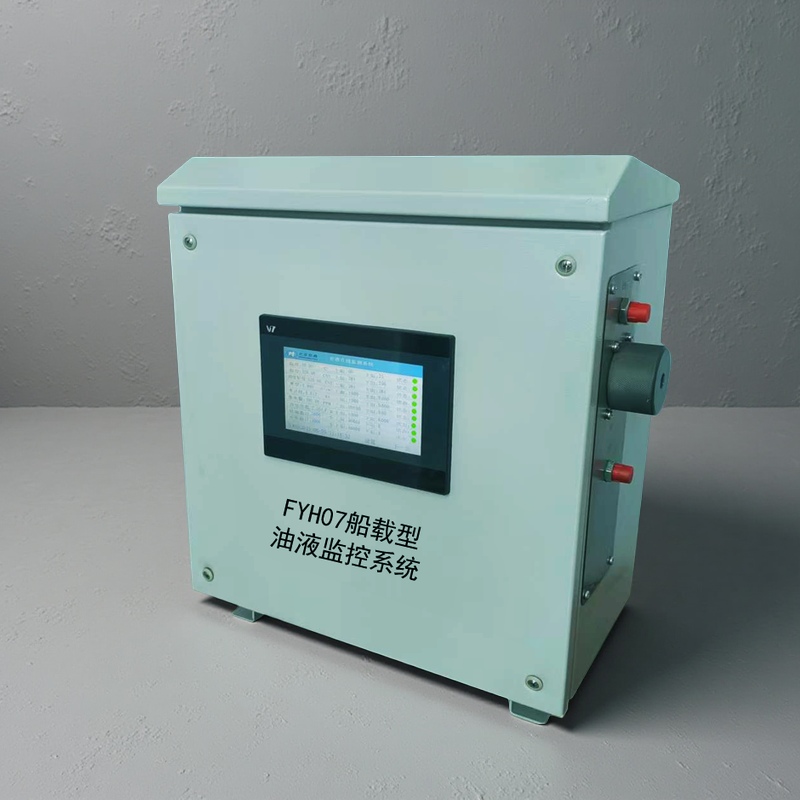

The FYH07 shipborne oil monitoring system has passed the long-term trial assessment of the shipowner and recently passed the appraisal and acceptance, and also meets the requirements of the China Classification Society (CCS) "Intelligent Ship Code". The 2024 version of the specification adds new requirements for status monitoring of high-speed diesel engines and battery systems, specifying the need to evaluate equipment health status through changes in oil performance, metal abrasive particles, and other data. Online oil monitoring is one of the key technologies for achieving the "smart cabin" additional mark (Mx). According to regulations, intelligent cabins require real-time status monitoring and health assessment of key equipment such as main engines, auxiliary engines, and propulsion systems, with oil parameters such as oil performance, abrasive content, and moisture being the core monitoring indicators.

The FYH07 shipborne oil online monitoring device mainly consists of oil particle pollution monitoring unit, oil moisture monitoring unit, comprehensive moisture monitoring unit, iron magnetic abrasive particle monitoring unit, kinematic viscosity monitoring unit, sampling unit, leakage monitoring unit, display screen and monitoring box, etc. It adopts online real-time monitoring technology to compensate for the lag of offline detection and form the real-time perception ability of "oil health" of the ship.

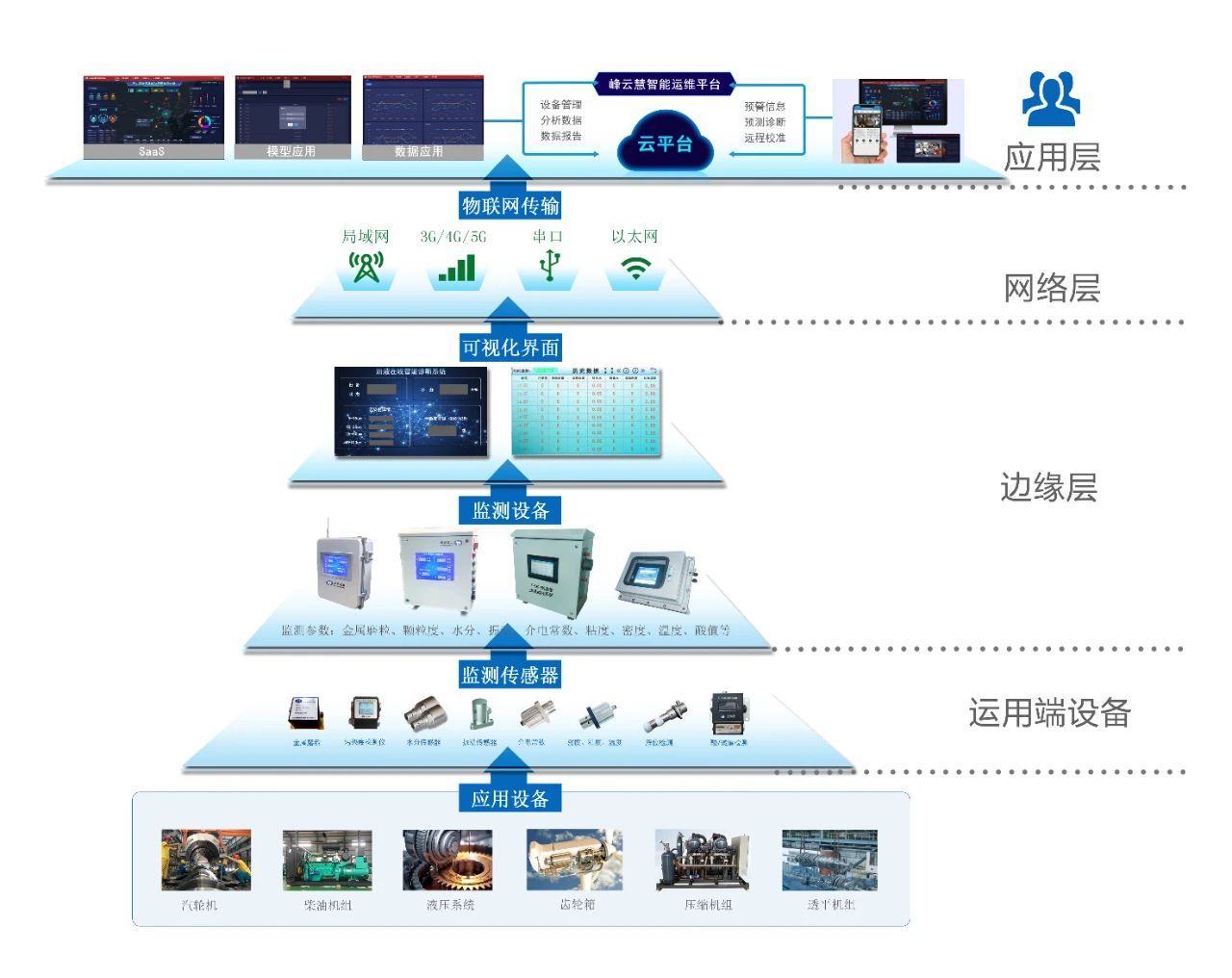

Through multi-sensor fusion and edge computing, marine oil online monitoring technology realizes real-time perception and intelligent diagnosis of oil state. Its core architecture includes the following technical modules:

1. Multi parameter sensing technology

Grinding particles and pollution monitoring

Moisture monitoring

Density and flow monitoring

Rapid detection of sulfur content

2. Intelligent Warning and Data Analysis Platform

When the concentration of iron (Fe) in the main engine lubricating oil suddenly increases to>100ppm, the system automatically triggers a secondary alarm, indicating the risk of crankshaft wear. A case study of a bulk carrier showed that the warning reduced the unexpected shutdown rate of the main engine by 45%. If the viscosity of hydraulic oil continues to decrease by more than 15% of the new oil standard, it may indicate the degradation of additives or dilution with fuel. The engineering ship successfully avoided hydraulic valve core sticking accidents through a real-time viscosity temperature compensation model. Online monitoring of ship oil products has surpassed the traditional scope of oil quality detection and become the decision-making center for power system health management. Grinding particle monitoring provides early warning of bearing failure, which is the "prophetic power" that oil monitoring endows ships with.