| Availability: | |

|---|---|

| Quantity: | |

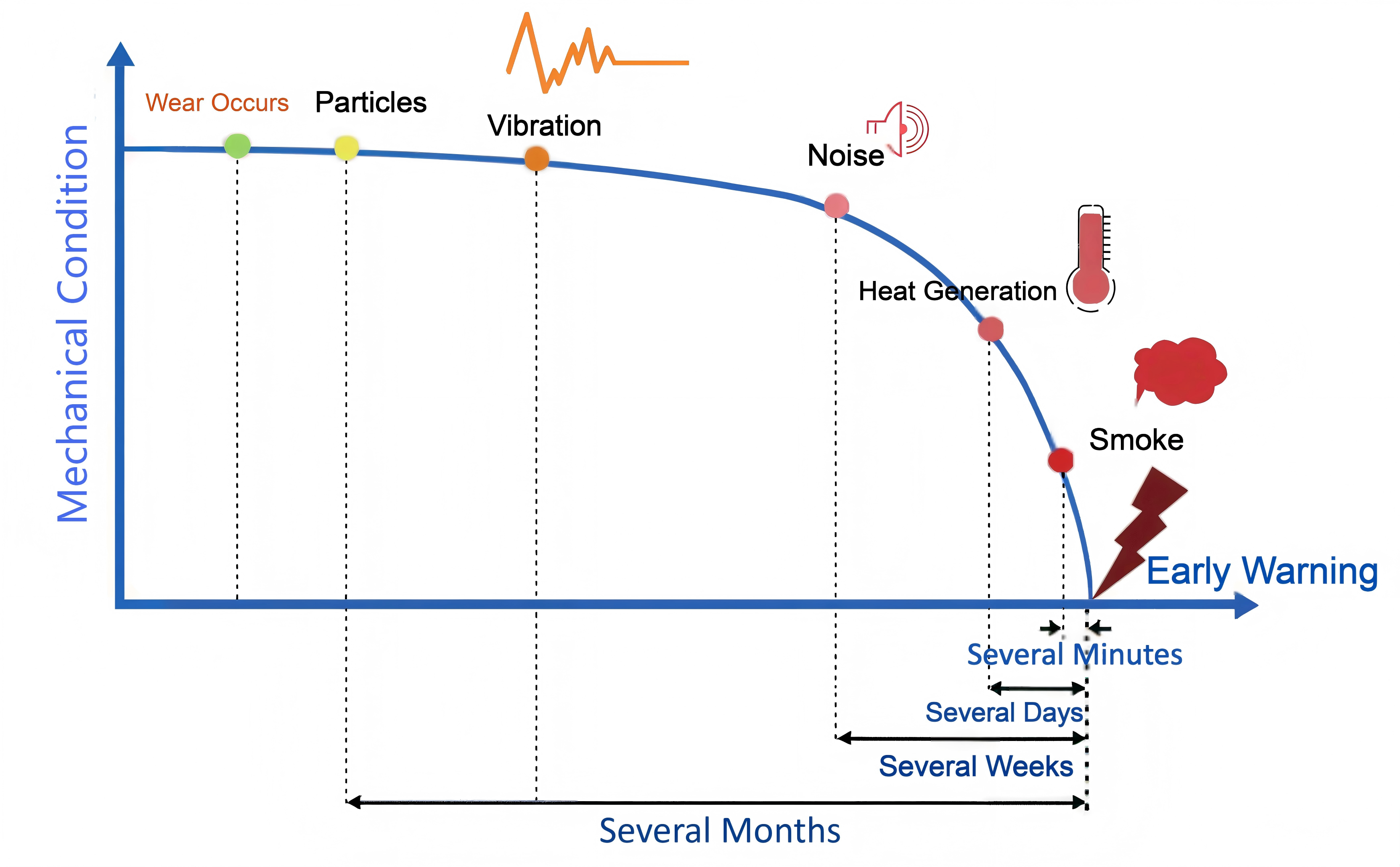

DC series online oil debris monitoring systems is an edge-cutting full flow on-line metallic particle sensor. It can provide the real-time particle counting and quantitative analysis by testing the ferrous and non-ferrous particles in lubricant resulted from mechanical wear and send reliable alarms on potential equipment fault. The reliability of oil debris monitoring systems comes from its simple and maintenance-free design. No cleaning is needed. No false alarm will be generat

MetalCheck Industrial Model MetalCheck Ruggedized Model

MetalCheck is able to efficiently monitor the wearing process of gearbox or bearing parts, and provide alarms in advance of serious damage and shutdown.

1. Real-time full flow monitoring.

2. Compact and smart. Easy installation.

3. Reliable data transmission. Transmission distance can be as far as 1000m

4. Automatic storage of data. Graphical display.

5. 100% detection of ferrous and non-ferrous particles within the range of sensitivity.

6. Based on the threshold value specially programmed for targets, for example engines, gearbox, etc, MetalCheck is able to help judge whether this a fault, where the fault is,

degree of fault, fault mode and type.

Model (Can be customized) | DC-5 DCH-5 | DC-1 DCH-1 | DC-12 DCH-12 | DC-14 DCH-14 | DC-19 DCH-19 | DC-38 DCH-38 | |

Public Chanel size | 5mm | 8mm | 12mm | 14mm | 19mm | 38mm | |

Micro ferrous Diameter | 30~200μm | 100~200μm | 125~300μm | 125~300μm | 125~300μm | 350~500μm | |

Medium ferrous Diameter | 200~300μm | 200~300μm | 300~500μm | 300~500μm | 300~500μm | 500~1000μm | |

Large ferrous Diameter | >300μm | >300μm | >500μm | >500μm | >500μm | >1000μm | |

Micro non-ferrous Diameter | 150~400μm | 450~600μm | 500~700μm | 500~700μm | 500~700μm | 500~1000μm | |

Large non-ferrous Diameter | >400μm | >600μm | >700μm | >700μm | >700μm | >1500μm | |

particle number per unit time | <100/s | <100/s | <100/s | <100/s | <100/s | <100/s | |

Qmin | 1L/min | 3L/min | 7L/min | 9L/min | 17L/min | 68L/min | |

Qmax | 10L/min | 30L/min | 70L/min | 90L/min | 170L/min | 680L/min | |

Working Temp | -40℃~75℃/-55℃~135℃( DCH Ruggedized) | ||||||

Oil Temp | <85 ℃ /<260℃( DCH Ruggedized) | ||||||

Pressure | <2 Mpa/<3MPa( DCH Ruggedized) | ||||||

Humidity | <95%RH | ||||||

Power Voltage | 18~36 VDC | ||||||

Protocol | CAN2.0 、RS485/RS422 | ||||||

Working current | <0.25A | ||||||

Communication Isolation voltage | 2500 VDC | ||||||

Isolation voltage | 1500 VDC | ||||||

Drive the node number | 32 | ||||||

Maximum working current when it is started | <1A | ||||||

DC Series MetalCheck Oil Debris Detector

Baud rate | CAN2.0 485 422 |

Communication Isolation voltage | 2500 VDC |

Isolation voltage | 1500 VDC |

Drive the node number | 32 |

Maximum working current when it is started | <1A |